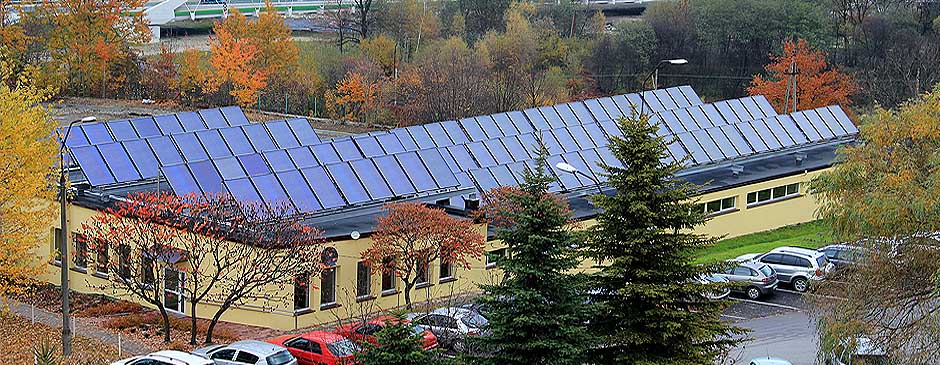

I. Solar tubing

made of copper, in compliance with the project design.

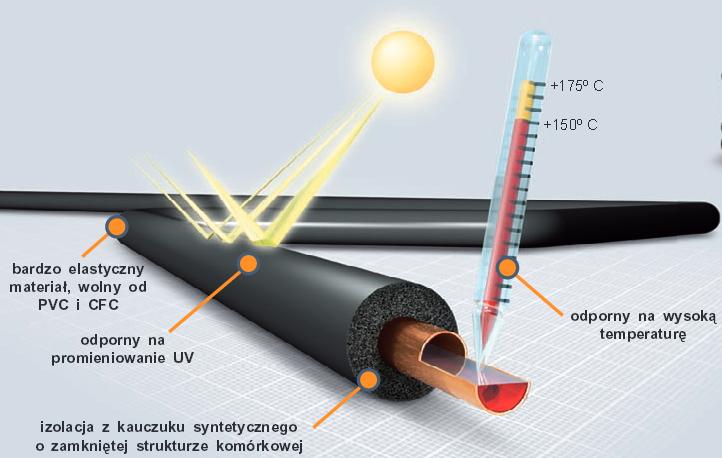

II. Insulation of outside tubing

HT/Armaflex external insulation was used, which should be placed along the entire tubing length in a way preventing leakage, unfolding, etc. > see

Moreover, insulation should meet the following criteria:

- Outdoor insulation heat conductivity of λ ≤ 0,038 W/(m*K)

- Resistance to UV radiation

- Resistance to high temperatures possibly generated by liquids flowing through insulated tubing

- Security against mechanical damage (e.g. birds’ beaks)

- Tubing must be insulated along its whole length, including pipes, fittings and pipe connections

- Insulation ends must be secured by aluminium rosettes

- Insulation edges and ends must be secured in the manner accepted by the insulation manufacturer

Source: http://www.armacell.com

III. Insulation of inside tubing

PAROC Section AluCoat T made of rockwool covered with a coat of reinforced aluminium foil was used. The insulation should be placed along the entire tubing length in a way preventing leakage, unfolding, etc. > see

Moreover, insulation should meet the following criteria:

- Outdoor insulation heat conductivity of λ ≤ 0,033 W/(m*K)

- Resistance to high temperatures possibly generated by liquids flowing through insulated tubing

- Insulation ends must be secured by aluminium rosettes

Source: www.paroc.pl

Source: www.paroc.pl